Perfect for: Road Bike Rider.

Tires: Designed to work with 700C*28C tire.

Cable routing: All internal cable routing.

Brake: Rim Brake.

Groupset: Mechanical and Di2 groupset compatible.

Material: High modulus carbon fiber.

Item No :

R04-C700C Aero Road Road Rim Brake Carbon Frame

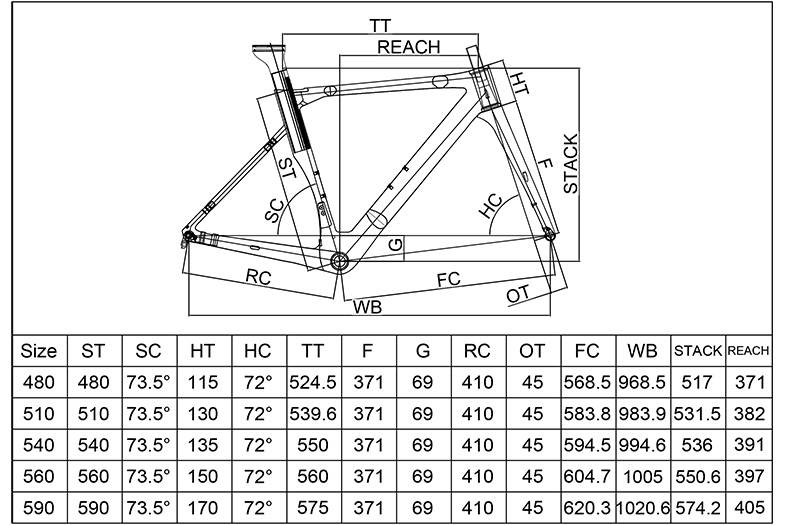

Product Specification:

| Frame | 700C Aero Road Road Rim Brake Carbon Frame R04-C |

| Size | 480, 510, 540, 560, 590mm |

| Fork | QTOUR specify aero carbon fork F06-V |

| Handlebar width | 400/420/440mm |

| Stem | 90/100/110/120mm |

| Headtube | Straight 1 1/2" head tube (Headset: FSA No.42ACB) |

| Weight | 1080g (540mm) |

| Seatpost | Specify Setback Adjustable Seatpost P04 |

| Bottom bracket | PressFit BB86 |

| Max tire clearance | 700C*28C |

| Brake Mount Type | Caliper Brake (Direct Mount) |

| Dropout | Front 9*100mm (QR), Rear 10*130mm (QR) |

| Groupset | Recommended install electronic shifting groupset(Not compatible with old rear derailleur without B-LINK, eg old 105 5800) |

| Integrated Handlebar | HR03 |

| Test Standard | ISO4210 |

| Warranty | 2 Years |

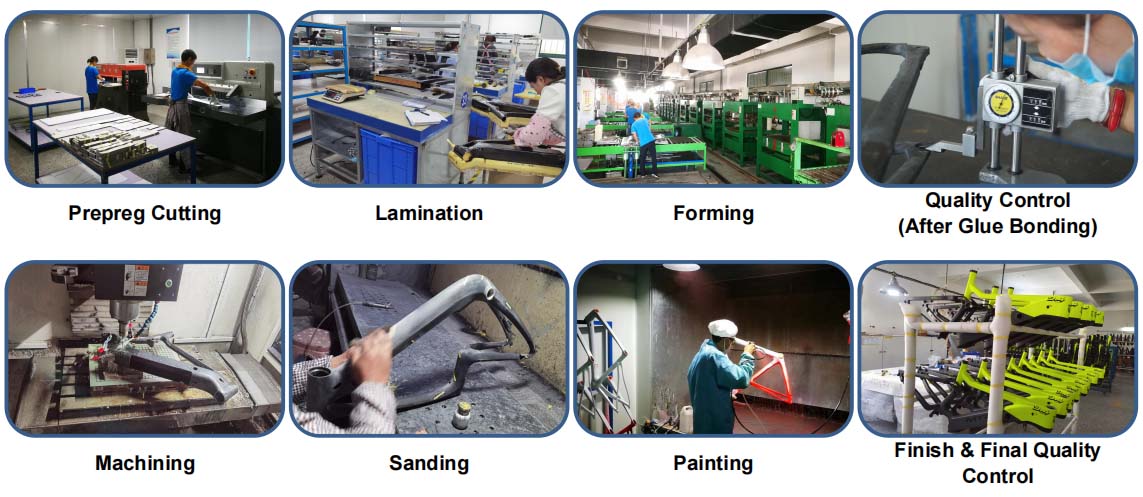

Company Information:

JiangSu QYH Carbon Tech Co.,Ltd Established in 2014. We’re a customer-oriented composite product manufacturer. We focus on the development of carbon fiber bicycle frame and also provide comprehensive manufacturing services for well-known brands among the world. And pay much attention to technological research and development, quality control.

We offer carbon composites development and manufacturing services for various products, such as bicycle frames, bicycle components, sporting goods, etc.

OEM/ODM (R&D)

1, Computer Aided Compression Stroke Simulation

By using Compression Stroke Simulation methods, We're able to improve kinematics quality, speed up analysis - in a straightforward and intuitive way.

2, Carbon Frame Shape & Structure Design

Ability to create unique frame and fork structural design to achieve stronger, more durable and the most importantly safer products for the clients.

3, Compatibility Testing for Frame and Components

When designing a bike frame, we collectively consider the frame, groupset, motor, battery and other accessories selections. To build your best complete-bike construction plan.

4, Quick Design Verification

Bike models are built using 3D printing software. These models help verify the integrity of the frame and its appearance before mass production. Not only does this create better communication between design and production, it also lowers production costs.

QUALITY CONTROL

1, 100% Inspection of Carbon Frame

QYH sticks to do 100% inspection to make product perfect. And every item must go through the inspection of finishing, specification, and performance testing on strength, stiffness, fatigue test so every finished product in QYH will be implemented rigid quality and quality security.

2, Raw Material Inspection

According to your company's specifications and international regulations, parts are randomly inspected. This process ensures that components are qualified and safe.

3, Sample Frame Service

Before mass production, R&D teams will working together with customers, assemble one complete bike for quality control examination. Several tests will be conducted to ensure the product's quality complies with regulations and meets customer needs.